The layout is not 100% historically accurate, so not every industry reflects an actual industry within the Saint Louis area during the nineteen-seventies. Locations of industries may not always be correct to the prototype. Some industries were actual Saint Louis rail customers during the nineteen-seventies, but other industries are complete fabrications. Here is information on each of our rail-served customers, grouped by layout location.

CITY OF SHREWSBURY

Kroger Company, Bakery Division

This plant provides baked goods which are distributed by truck to Kroger grocery stores. Incoming shipments of flour arrive both in boxcars and sometimes in those new covered hoppers. Molasses and sugar arrive by tank car; yeast and other perishables come in by mechanical reefers. Other supplies (packaging, other ingredients) arrive by boxcar. Locals and visitors delight in the smell of the freshly baked products made here.

C. Griswald Manufacturing

Fans of National Lampoon’s Christmas Vacation will recognize Chevy Chase’s character, Clark Griswald, as the inspiration for this fictitious company’s name. The plant is famous for its non-nutritive semi-osmotic cereal additive products.

Cupples Manufacturing

Cupples Products manufactures curtain wall, which are used in skyscrapers around the world. Curtain wall is the material in modern skyscrapers that surrounds the outside of a typical modern commercial building. The actual plant and headquarters was located on 10 acres in nearby Maplewood.

Osage Box Company

We can’t tell you anything about this customer except that it is listed as a St. Louis rail-served industry in the OpSig Industry Database.

Our guess is that the plant receives paper and corrugated fiberboard by rail.

Mizerany Warehouse

Steve Mizerany was a zany St. Louis appliance dealer who roller-skated through his store

and squealed pitches over local radio stations during the 1970s and ’80s. We don’t know if he had a separate warehouse but we gave him one anyway to store all those televisions and appliances.

SOULARD NEIGHBORHOOD

Anheuser-Busch Brewery

This renowned Saint Louis brewery is located near the Soulard Neighborhood. Breweries such as this one receive a wide variety of shipments. Various grains arrive by covered hopper and are then distributed into storage silos by the elevator; hops are received in refrigerated boxcars (reefers). Bottles and bottle caps, aluminum for cans, and packaging materials arrive by boxcar. Used bottles and kegs are loaded into boxcars and shipped back to the plant for cleaning and reuse. Diatomaceous earth, a naturally occurring, soft, siliceous sedimentary rock that can be crumbled into a fine white to off-white powder, is received by covered hopper and stored in the mineral silos. It is used in the filtration process. Fuel for the modeled plant is provided by liquid propane and coal, so these loads are also received by rail. A gondola on the cullet track receives broken glass, and is shipped to a recycling plant when full.

On the shipping end, the plant ships finished product (lots of beer) by boxcar. For each gallon of beer

produced, about 10 pounds of spent grain are left over. Spent grain is used as a livestock feed

supplement, in composting, and in baking. (More recently it has also seen use as a bio-fuel.) Spent

grain is shipped in bulk in covered hoppers for both fertilizer and feed. Bagged feed is shipped via truck

from this plant.

CARONDELET

U.S. Steel

Located near the confluence of River Des Peres and the Mississippi River, Carondelet was once a thriving industrial district. Two very large Iron Works (Jupiter and Vulcan) employed thousands of workers. A Marine iron works produced numerous ships here.

The principal raw materials for an integrated mill are iron ore, limestone, and coal (or coke). These materials are charged in batches into a blast furnace where the iron compounds in the ore give up excess oxygen and become liquid iron. There isn’t enough layout space to represent the receiving of massive iron ore shipments, so we bailed on that. However, our modeled plant does receive coal in coal hoppers and lime loads in covered hoppers, but not in the amount that a prototypical plant would. We’re living in a truncated free-lance dream world here.

The plant also receives boxcars loaded with various materials and supplies, tank cars of diesel fuel to

power the yard goat, and gondolas loaded with tons of rusty old scrap metal. (We recycle here.)

Empty coil cars and gondolas are constantly flowing into the facility, and sent out with loads from the

rolling, pipe, and wire mills located on the property. Slag, which occurs as a molten liquid melt and is a

complex solution of silicates and oxides that solidifies upon cooling, is shipped from the plant in open

hoppers. Other outbound shipments includes bags of various chemical products created as a by-product

of the operation, and tank cars of coal tar, another by-product of production.

Slag is a residue is comprised of minerals such as silica, alumina and titanium from iron sand, as well as

other combinations of calcium and magnesium oxides derived from other raw materials. It is often used

as a road base. With high particle density and hardness, slag has superior wear resistance, which makes

it an excellent aggregate for asphalt concrete. Other applications of slag include rail ballast, soil

conditioner, sewage treatment and even artificial ocean reefs.

Coal tar, a black, sticky liquid thicker than water, is produced when coal is heated in the absence of air, a

process called destructive distillation. Much coal tar is produced by the steel industry as it produces

millions of tons of coke each year to fuel the furnaces used in separating iron from its ores. Uses for

coal tar are numerous, and include everything from industrial electrodes to medicinal shampoos.

Bendix Corporation

This brake production facility receives shipments of steel direct from the mill. Other products received (mostly by boxcar) at this plant are phenolic resin, fiberglass strand & iron and aluminum oxides. Boxcar

loads of graphite and rubber are also received. Coiled steel is unloaded on the crane track & inside the structure. Boxcar loads are received at the receiving dock.

Pillsbury Mills

“Nothin’s as lovin’ as something from the oven”, and there’s always something baking in the oven at the product testing building; most days you can smell the tantalizing aroma for miles. The shipping part of operations is all we had room to model. Covered hopper loads of flour and sugar are shipped daily, so there’s always the need for empty covered hoppers at the plant. Cake mix, muffin mix, pancake mix, and donut mix is shipped out in boxcars. Crews working the plant like to stop by the test kitchen for free samples whenever working this plant. The Pillsbury plant in St. Louis was located just north of the downtown area. Present day Carondelet is the real home and headquarters of Italgroni, which mills large quantities of semolina and durum flour at this St. Louis plant.

CHECKERBOARD SQUARE

Purina Mills

Purina is the largest rail customer in this area. Grain is hauled in and milled, and the smell of processing fills the air for miles around, as dog food and other animal feeds are manufactured. On the receiving side,

the plant also gets boxcar shipments of paper products & other packaging supplies. Various

supplements and other additives are received by both boxcar and tank car. Shipping of products is on the other side of the plant. Bagged products are loaded into empty boxcars at the shipping dock, while bulk finished product is loaded into covered hoppers (and sometimes grain-door equipped boxcars). Unloaded covered hoppers go to the cleaning track before being moved to the bulk shipping track.

LASALLE PARK

Coca-Cola Bottling

There is a Coke bottling plant in St. Louis, located on Chouteau Ave. On the layout, we put ours in the LaSalle Park area just to confuse the masses. The building is modeled from Walther’s Brook Hill Farm Dairy kit.

Our plant receives empty bottles, bottle caps, carbon dioxide gas, and sugar, and other secret ingredients by rail.

Eagle Distributing

There really was a paper company doing business by this name, but it was located in Fairbanks, Texas. We don’t know where that is exactly, but we liked the name.

Our modeled company distributes appliances. Shipments are received by rail and all shipping is done by truck.

Walker Seed Company

(J. Walker & Sons)

Walker Seed is a fictitious company named in honor of the late Jim Walker, who frequently operated on this layout. We miss you Jim, but your memory lives on in this model.

Wetterau Wholesale

Wetterau went public in 1961 with the sale of 100,000 shares of stock and changed its name to Wetterau Foods Incorporated, but the company’s history goes back to 1867 when young George H. Wetterau left Germany and moved to St. Louis.

Reefers and boxcars arrive for unloading on the track behind the buildings. As illustrated by the photo, shipping is done by truck.

CHOUTEAU NEIGHBORHOOD

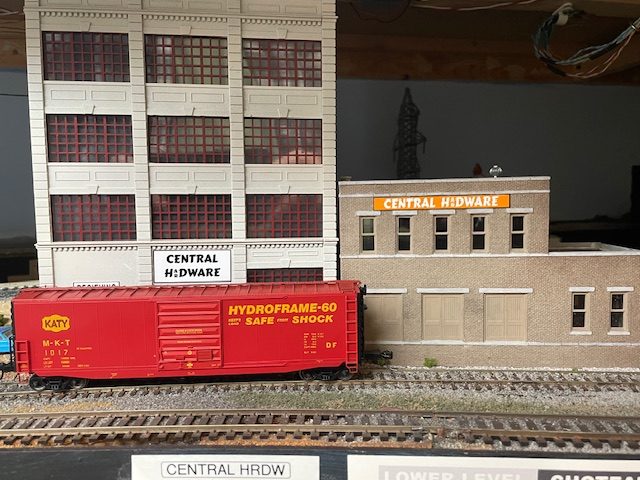

Central Hardware

“Everything from scoop to nuts!” was the slogan of Central Hardware. This midwestern hardware store chain was based in St. Louis, Missouri. They were one of the first home improvement store chains to regularly build stores topping 50,000 square feet. This warehouse model is a tribute to that company.

Reiss-Moran Lumber

Spring Avenue Team Track

TOWER GROVE

River Cement

Sulphur Springs Quarry

Blue Star Ready Mix

Ellendale Team Track

MFA Elevator at Baden

Farmers Feed & Supply

Baden Street Department

Commercial Propane

Baden LPG

Baden Station